The calculation of the sawblade optimal finish quality - OMER

Main menu:

- Maximum RPM of tools

- The calculation of the sawblade teeth number

- The calculation of optimal sawblade diameter

- The calculation of the sawblade optimal finish quality

- The calculation of router diameter

- The calculation hw cutter feed rate

- The calculation of the maximum profiled cutter diameter

- The calculation of the finish quality grade

- The calculation of the optimal cutter speed

- The calculation of the optimum number of cutter teeth

The calculation of the sawblade optimal finish quality

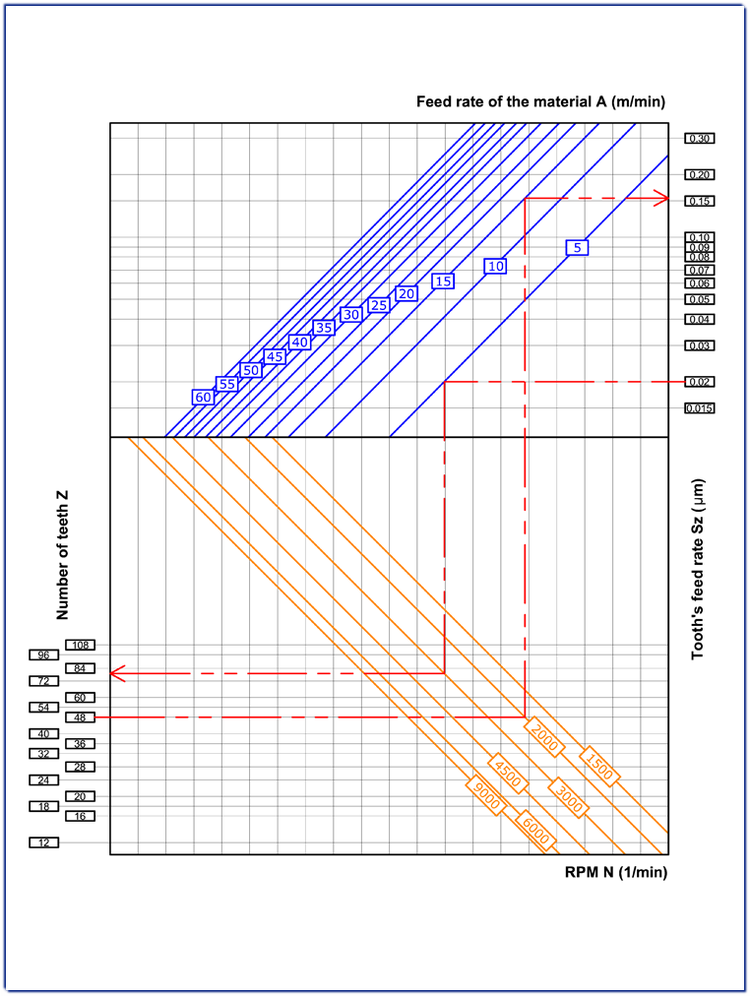

The technical table for the calculation of the optimal quality of finish, of the feed rate of the material, the number of teeth and the RPM for the circular sawblades.

To calculate the optimal finish quality of the circular saw blade according to the diameter, number of teeth and the RPM of the circular blade, You can send the request with the data necessary fields.We will answer you without any your commitment, in a short time. Otherwise you can use the table below, following the examples subscribed.

Optimal finish quality Sz (μm) |

||||||

Softwood along grain |

Softwood across grain |

Hardwood |

Chipboard |

Plywood |

Veneered |

Aluminium and plastic |

0,20- |

0,10- |

0,06- |

0,10- |

0,05- |

0,05- |

0,02- |

Example 1:

Obtain the degree of finish quality Sz = 0.15 for the processing of hard wood, using the circular sawblade with number of teeth Z = 48, rpm N = 2,000 1/min and the feed rate of the material A = 15 m/min.

From the point resulting from the vertical left (Number of teeth) Z = 48 follow the line up to the point of the diagonal (rpm) N = 2,000 1/min. Proceed vertically to the second diagonal (feed rate of the material) A = 15 m/min, and then horizontally to the right vertical (tooth's feed rate) Sz = 0.15 microns.

Example 2:

Determine the number of teeth of the circular sawblade necessary fields to obtain the degree of finish quality Sz = 0.02 um for the working of chipboard with plastic coating, using the circular sawblade with a rpm N = 3,000 rpm 1/min and the feed rate of material A = 5 m/min.

From the point corresponding to the vertical right (tooth's feed rate) Sz = 0.02 mm follow the line up to the point of the diagonal (feed rate of the material) A = 5 m/min. Proceed vertically to the second diagonal (rpm) N = 3000 1/min, and then horizontally to the left vertical (number of teeth) Z = 84.